Repair of servomotors and electric motors

ALPHITAN provides repair services for servomotors and electric motors.

For over 40 years, the ALPHITAN Group has been ensuring the operational readiness and repair of all types of servomotors and electric motors. We specialize in the repair of all types of servomotors and electric motors, including DC, asynchronous, and synchronous (brushless) motors.

Thanks to our expertise, we work on a wide range of rotating electrical equipment technologies, such as:

- Servomotors and associated control systems

- DC electric motors

- Electric motors of other technologies: asynchronous, etc.

- Motors for embedded railway or other systems

- Speed variation and power electronics

.jpg)

Why repair servomotors and electric motors?

First and foremost, repairing servomotors or electric motors helps improve availability and/or ensure the quick restoration of your industrial installations or embedded systems. Repairing electrical equipment also extends the lifespan of your industrial installations while minimizing costs. Indeed, repairs are generally more cost-effective than purchasing new equipment. Lastly, servicing your motors (maintaining operational readiness) helps prevent unexpected failures and enhances the reliability of your industrial installations.

The repair of servomotors

The ALPHITAN Group offers comprehensive repair solutions for a wide range of brands and servomotor technologies used in the French industrial sector. We understand that each type of servomotor has its own specificities, which is why we tailor our interventions to meet the needs of your equipment.

Our experts specialize in the repair of various servomotor technologies:

- Permanent magnet DC servomotors

- Controlled asynchronous servomotors

- Wound-field servomotors

- Synchronous (brushless) servomotors

- Stepper servomotors

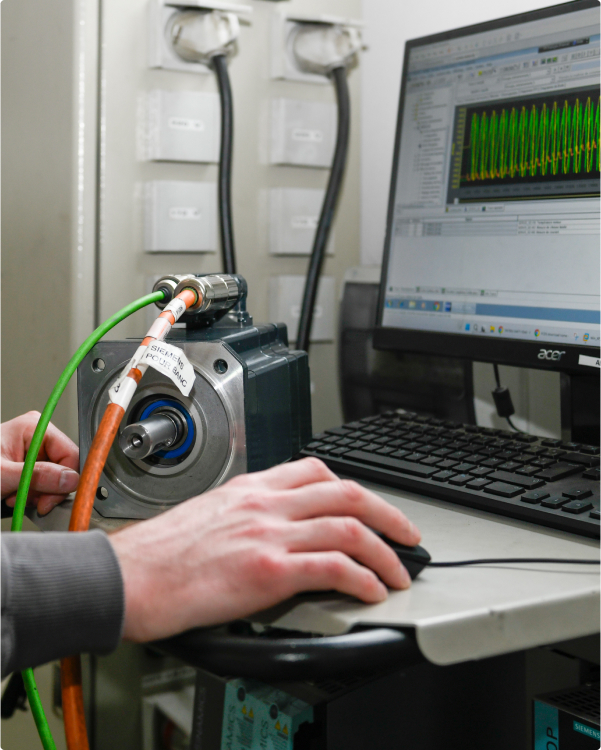

Our technicians repair servomotors daily from various brands, including SIEMENS, BOSCH/REXROTH, FANUC, PARKER, SCHNEIDER, NUM, LEROY-SOMER, ALLEN BRADLEY, LENZE, and more.

The repair of servomotors

The ALPHITAN Group offers comprehensive repair solutions for a wide range of brands and servomotor technologies used in the French industrial sector. We understand that each type of servomotor has its own specificities, which is why we tailor our interventions to meet the needs of your equipment.

Our experts specialize in the repair of various servomotor technologies:

- Permanent magnet DC servomotors

- Controlled asynchronous servomotors

- Wound-field servomotors

- Synchronous (brushless) servomotors

- Stepper servomotors

Our technicians repair servomotors daily from various brands, including SIEMENS, BOSCH/REXROTH, FANUC, PARKER, SCHNEIDER, NUM, LEROY-SOMER, ALLEN BRADLEY, LENZE, and more.

The repair of electric motors

For 70 years, we have been providing repair services for rotating electrical systems. Since 2008, we have played a major role in the overhaul and operational maintenance of embedded equipment, particularly in the railway sector, with numerous contracts in France and abroad. We possess extensive expertise in the maintenance of rotating electrical systems, including winding (see dedicated page), electromechanical repair, precision mechanics, testing, and validation.

Our technicians and experts specialize in the repair and maintenance of various types of electric motors:

- DC motors

- Asynchronous, synchronous, or controlled asynchronous motors

- Single-phase or three-phase motors

- Generators

- Transformers

- Gear motors

- Motor fans

- Motor pumps, etc.

The ALPHITAN Group and its electrical equipment experts specialize in repairing various brands of electric motors, including ABB, ALSTOM, BALDOR, BAUMULLER, BBC, CEM, CFR, DEMAG, EMERSON, FENWICK, GROSCHOPP, JEUMONT-SCHNEIDER, LENZE, LEROY-SOMER, MAGNETIC, MOOG, PERSKE, RAGONOT, SEW, SICME, SIEMENS, TT ELECTRIC, THRIGE ELECTRIC, UNELEC, and WEG.

The repair of electric motors

For 70 years, we have been providing repair services for rotating electrical systems. Since 2008, we have played a major role in the overhaul and operational maintenance of embedded equipment, particularly in the railway sector, with numerous contracts in France and abroad. We possess extensive expertise in the maintenance of rotating electrical systems, including winding (see dedicated page), electromechanical repair, precision mechanics, testing, and validation.

Our technicians and experts specialize in the repair and maintenance of various types of electric motors:

- DC motors

- Asynchronous, synchronous, or controlled asynchronous motors

- Single-phase or three-phase motors

- Generators

- Transformers

- Gear motors

- Motor fans

- Motor pumps, etc.

The ALPHITAN Group and its electrical equipment experts specialize in repairing various brands of electric motors, including ABB, ALSTOM, BALDOR, BAUMULLER, BBC, CEM, CFR, DEMAG, EMERSON, FENWICK, GROSCHOPP, JEUMONT-SCHNEIDER, LENZE, LEROY-SOMER, MAGNETIC, MOOG, PERSKE, RAGONOT, SEW, SICME, SIEMENS, TT ELECTRIC, THRIGE ELECTRIC, UNELEC, and WEG.

.jpg)

Are you looking for new or used electrical equipment?

You can search for parts for your electrical equipment using a specific reference or by browsing the categories in our product catalog.

Motors and servomotors

Motor and servomotor components

Industrial equipment

Electromechanics

Cables, connectors, and switches

Workshop equipment and consumables

Electromechanical and mechanical repair at ALPHITAN

Our Electromechanical Activities

- Handling of electromechanical equipment Identification of the part, preliminary analysis, and rapid quotation issuance

- Repair of electrical equipment Cleaning, additional expertise, and operational restoration of the motor

- Equipment testing Testing, adjustments, and configuration of electrical equipment

- Repair finalization Validation on a test bench with a detailed intervention report

Our Mechanical Activities

- Machining of mechanical parts Manufacturing of flanges and other obsolete parts through machining, milling, or other methods

- Enhancing part sealing Re-sleeving of bearing seats on shafts and flanges

- Mechanical equipment repair Re-metalizing and restoring shafts through molten metal projection

- Equipment stabilization Dynamic balancing with a balancing certificate

ALPHITAN: 7 electric motor repair workshops

With six workshops in France and one in Germany near Hanover, the ALPHITAN Group has significant resources for the repair and maintenance of electric motors and servomotors. Among them, you will find:

- Balancing equipment (dynamic control): for balancing rotating elements from 200 grams to 2 tons

- Impregnation and curing equipment: including a vacuum and pressure impregnation tank (+5 bars)

- Mechanical equipment: for machining, re-metalizing, and welding (TIG, high-frequency, etc.)

- Testing and control equipment: featuring over 400 measurement and inspection devices for electrical, mechanical, and metrological assessments, including surge testers for windings and more than 150 drives, CNC controllers, and servomotors for dynamic testing and inspection.